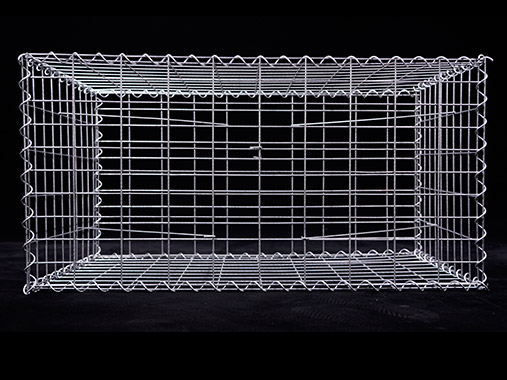

Welded Gabion is made of welded wire mesh panels assembled with spirals, locking pins and stiffener. Each gabion panel is composed of rugged high tensile wire coated by a thick, corrosion-resistant layer of zinc.

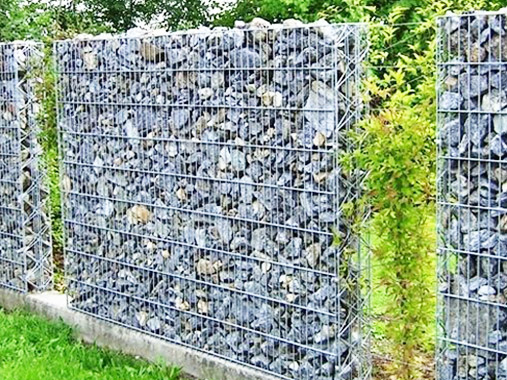

The wire is also available with a tough, durable pvc coating. Welded gabion could be used for prefilled on site construction which is quick and easy. They have a variety of applications such as retaining walls for commercial, industrial and road project, landscaping, erosion control.

| Mesh Sizes (mm) |

Welede gabion dimensions and volumes | Wire diameter | ||||

| L(M) | W(M) | D(M) | Capacity(m³) | Number of diaphragm | ||

| 50*50 75*75 50*100 100*100 |

1 | 0.5 | 0.3 | 0.15 | 0 | Mesh Wire: 3.0mm,3.2mm, 3.4mm,3.8mm,4.0mm |

| 1 | 0.5 | 0.5 | 0.25 | 0 | ||

| 2 | 1 | 0.5 | 1 | 1 | ||

| 1 | 1 | 1 | 1 | 0 | ||

| 2 | 1 | 1 | 2 | 1 | ||

| 4 | 2 | 0.3 | 2.4 | 3 | ||

| 6 | 2 | 0.2 | 2.4 | 5 | ||

| Other specifications can also be customized processing. | ||||||

Advantage:

1.Easy to install

2.High zinc coating thus anti-rust and anit-corrosive

3.Low cost

4.High security

5.Colorful stones and shells etc can be used with gabion mesh to make beautiful appearance

6.Can be made into various shapes for decoration

How to install welded Welded Gabion?

Step 1. Ends, diaphragms, front and back panels are placed upright on the bottom section of wire mesh.

Step 2. Secure panels by screwing spiral binders through the mesh openings in adjacent panels.

Step 3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing, and crimped over the line and cross wires on the front and side faces. None are needed in interior cells.

Step 4. Welded gabion box filled with graded stone by hand or with a shovel.

Step 5. After filling, close the lid and secure with spiral binders at the diaphragms, ends, front and back.

Step 6. When stacking tiers of the welded gabion box, the lid of the lower tier may serve as the base of the up